Industrial pressure washers are essential tools for commercial and industrial cleaning jobs. Using high-pressure water, they remove dirt, grime and stubborn stains from surfaces such as brick walls, concrete, tiles and metal. Pressure washing is a cost-effective and efficient way to clean surfaces quickly, reducing manual labour while maintaining hygiene and operational standards.

High-pressure cleaners, also known as pressure washers, are designed to suit a wide range of cleaning tasks across industries. They are available in various models, including electric, petrol and diesel-powered units, each suited to different applications. Pressure cleaners can also be mobile for easy relocation, making them ideal for construction sites, factories, warehouses and other commercial environments.

Key Considerations for Industrial Use

- Pressure (PSI): Industrial applications generally require 2,900–5,000 PSI. Anything above 3,500 PSI is for high-intensity cleaning tasks.

- Power Source: Petrol or diesel models provide mobility and high power for large sites, while electric models suit lighter industrial applications.

- Durability: Look for steel or stainless-steel frames, reliable pumps and certified engines for daily heavy-duty use.

- Accessories: Consider including lances, nozzles, hoses and detergent injection systems for versatility.

- Ease of Use: Petrol washers offer power but require training; electric models are simpler and safer for less experienced operators.

Types of Industrial Pressure Washers

Industrial pressure washers come in several classes, each designed to handle different surfaces and cleaning intensities:

Electric Pressure Washers

Electric pressure washers are ideal for light to medium-duty commercial cleaning jobs. They are quieter, easier to maintain and perfect for cleaning sensitive surfaces like tiles or indoor areas.

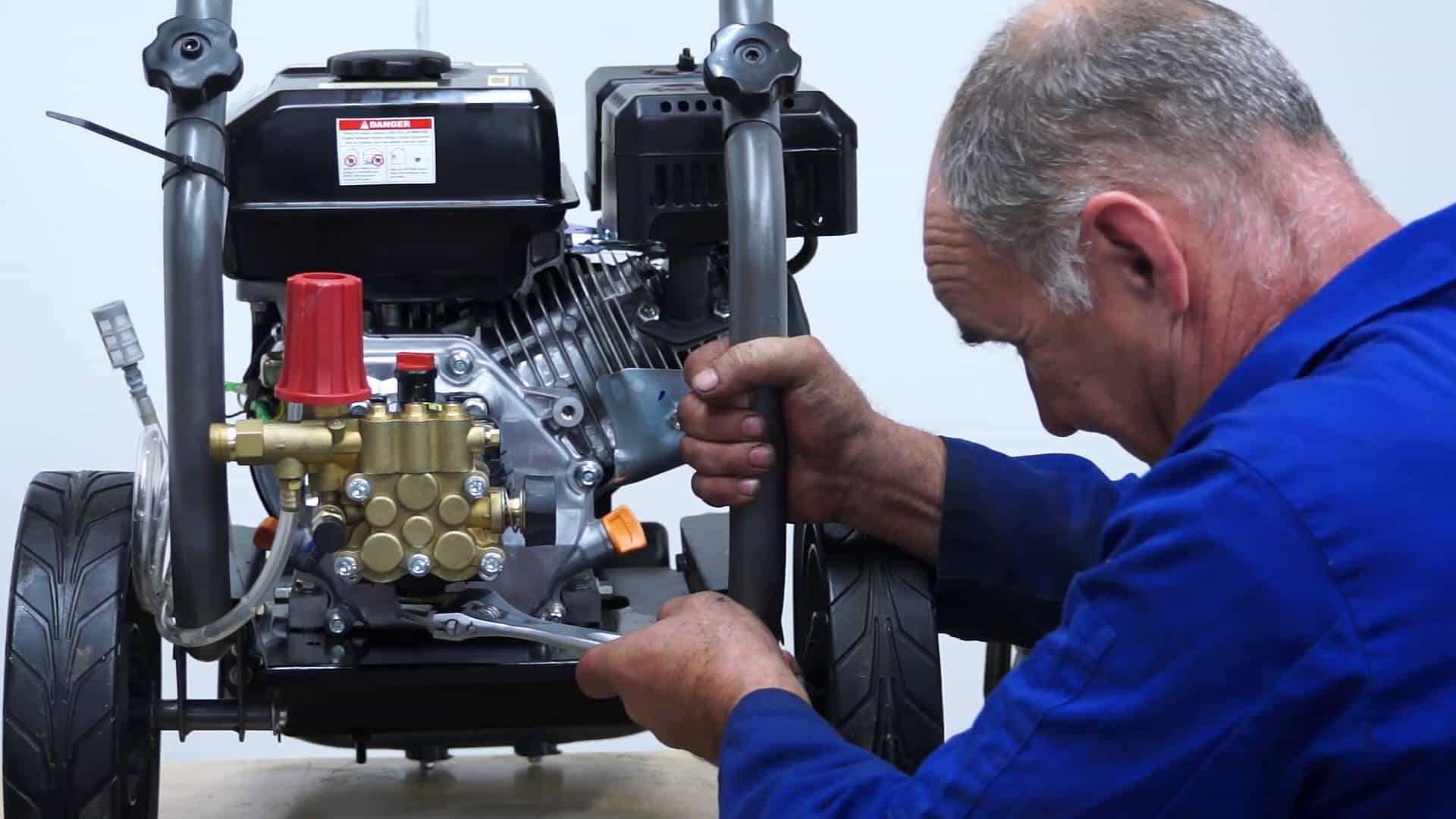

Petrol & Diesel Pressure Washers

Petrol and diesel-powered units are built for heavy-duty industrial applications. With high-pressure outputs, often up to 5,000 PSI, these machines can tackle stubborn stains, grime, and large-scale cleaning jobs on brick walls, concrete, machinery, and outdoor surfaces.

Hot Water Pressure Washers

Hot water units are highly effective for cleaning greasy surfaces and stubborn stains. They are ideal for industries such as food processing, manufacturing and commercial kitchens where disinfectants may be used alongside hot water to clean and sanitise surfaces.

Steam Pressure Washers

Steam pressure cleaners provide an environmentally friendly alternative. They use high-temperature steam to clean and disinfect surfaces, removing tough grime without the need for harsh chemicals.

Mobile Pressure Washers

Mobile units are designed for easy transportation across worksites. They are perfect for jobs requiring flexibility, such as outdoor construction sites, public areas or locations with limited access.

Features and Benefits

Industrial pressure washers are equipped with features to enhance cleaning efficiency and safety:

- High Pressure Output: Cleans surfaces quickly, removing dirt, grime and stubborn stains.

- Adjustable Triggers: Allow precise control of water flow, ideal for delicate surfaces.

- Durable Construction: Built to withstand heavy industrial use and harsh conditions.

- Detergent and Disinfectant Compatibility: Enhances cleaning and sanitising effectiveness.

- Variety of Nozzles and Accessories: Tailor water pressure and spray patterns to different surfaces.

- Safety Features: Automatic shutdown, trigger locks and durable housings reduce the risk of accidents.

High-pressure industrial washers also provide financial value by saving time and money. Efficient cleaning reduces labour costs while prolonging the life of surfaces and equipment.

Choosing the Right Pressure Washer

Selecting the right high-pressure cleaner depends on several factors:

- Cleaning Job Requirements: Consider the type of surface (concrete, brick walls, tiles) and cleaning intensity.

- Hot or Cold Water: Hot water or steam units for grease and disinfecting tasks; cold water for general cleaning.

- Power Source: Electric units for lighter jobs; petrol or diesel for high-demand industrial tasks.

- Mobility: Mobile units for flexible site usage.

- Accessories: Detergents, hoses, nozzles and lances to maximise cleaning efficiency.

- Safety Features: Trigger locks, automatic shutdown and robust pump construction.

Industrial Applications

Industrial pressure washers are widely used across industries:

- Construction and Infrastructure: Cleaning brick walls, concrete surfaces and construction machinery.

- Agriculture: Removing dirt and debris from equipment, storage facilities and vehicles.

- Manufacturing: Maintaining hygiene in factories, warehouses and production lines.

- Commercial Cleaning: Pavements, tiles and public areas requiring frequent cleaning.

- Vehicle Maintenance: Trucks, buses and industrial vehicles often require high PSI units for grime removal.

Comparison of Popular Industrial Models

BAR 3513G HJV (Petrol)

- Heavy-duty petrol washer, up to 5,000 PSI.

- Best suited for intense industrial cleaning.

- Mobile and durable, ideal for outdoor worksites.

BAR Avant Professional Hot Water

- Industrial hot water cleaner with thermostat and bypass valve.

- Perfect for sanitising surfaces and removing grease.

- Heavy-duty design for regular professional use.

- Australian-certified high-pressure washer.

- Versatile for both commercial and industrial cleaning jobs.

- Hot and cold water options are available.

- Powerful cold water washer, ideal for medium-duty cleaning and smaller applications.

- Suitable for tiles, concrete, and indoor surfaces.

- Lightweight and easy to transport.

Industrial High-Pressure Washer Comparison

| Model | Power Source | Max PSI | Ideal Use | Key Features | Notes |

| BAR 3513G HJV | Petrol | Up to 3500 PSI | Heavy-duty industrial cleaning | Honda engine, Australian certified, suitable for professionals | Excellent for tough grime on machinery and concrete surfaces, portable for on-site jobs |

| BAR 4013C-H | Petrol | 4000 PSI | Industrial & commercial | Honda engine, robust steel frame, all-metal components | Reliable for daily heavy-duty use, good for industrial site cleaning and vehicle fleets |

| BAR 4023CG-HEC | Petrol | 4000 PSI | Industrial cleaning | Honda-powered, stainless steel covers, durable | Suitable for construction and manufacturing facilities |

| BAR KL1600A | Cold water, Electric | 1600 PSI | Medium industrial cleaning | Cold water pressure, electric powered | Best for lighter industrial tasks, safer for less experienced operators |

| BAR KT1800 | Electric | 1800 PSI | Medium-duty industrial | Comet electrical pump, three axial pistons | Suitable for semi-professional applications with moderate pressure needs |

| BAR K Steel K9.21-21180 | Cold water, Electric | 2610 PSI | Medium-duty industrial | Ready-to-use, compact, steel frame | Ideal for smaller industrial facilities and mobile cleaning tasks |

Safety Considerations

Safety must always come first when operating industrial pressure washers. These powerful machines can cause damage or injury if not handled correctly, so it’s important to follow best practices at all times.

- Always wear protective gloves, safety glasses, and appropriate footwear.

- Use the correct nozzle and water pressure for the surface.

- Ensure regular servicing and maintenance of pumps and machines.

- Be cautious with high PSI units, especially steam or hot water washers.

- Follow manufacturer instructions for safe operation.

By following these precautions, operators can ensure safe, efficient cleaning while avoiding unnecessary risks or costly damage to equipment and surfaces.

Cleaning Effectiveness

High-pressure washers are designed to deliver outstanding results across a wide range of cleaning jobs. Their versatility makes them suitable for industries that require fast, robust and reliable cleaning solutions.

- Hot water units enhance the cleaning of grease and industrial grime.

- Detergents and disinfectants can be applied through pressure cleaners.

- Steam washers provide chemical-free cleaning and sanitisation.

- Regular maintenance ensures consistent performance and longevity.

When matched to the right job and properly maintained, these machines can quickly restore surfaces like concrete, brick walls, tiles and equipment to a clean, professional standard.

Purchasing and Maintenance

It’s essential to choose a system that’s right for the intended purpose. Engaging experienced consultants or service providers can help determine the correct PSI, water temperature and accessories for your cleaning needs. Accessing specialist knowledge and industry insights ensures efficient, safe, and effective cleaning solutions.

When buying an industrial pressure washer:

- Choose reliable brands such as BAR, Kranzle, and Crommelins.

- Consider the total cost of ownership: purchase, maintenance and operating expenses.

- Ensure access to spare parts and authorised servicing.

- Review warranty and customer support options.

- Keep detailed records of maintenance for long-term reliability.

If you need advice on service intervals or spare parts, our team is always happy to help.

Need Further Advice On Industrial Pressure Washer Options?

Industrial pressure washers are essential tools for tough cleaning challenges across industries. Choosing the right model, understanding features and implementing proper safety and maintenance practices ensures clean surfaces, operational efficiency and long-term value. Whether you need mobile units, hot water washers, or heavy-duty petrol models, selecting the correct high-pressure cleaner will save time, money and effort in your cleaning operations.

Our expert team supplies, services and repairs industrial pressure washers across Melbourne and the Mornington Peninsula. For personalised advice, servicing or quotes, contact the Melbourne Jetter Centre on (03) 9792 2350, or drop in for a chat.