The Importance of Comparing Flow Rate vs PSI When Deciding On Commercial High-Pressure Washers and Jetters

When choosing commercial and industrial high-pressure washers or jetters, understanding the roles of flow rate vs PSI (pounds per square inch) is critical to selecting the right equipment. While PSI determines the force of water, flow rate, measured in litres per minute (LPM), controls how much water is delivered. For commercial users, flow rate is often the defining factor for effective cleaning and clearing applications.

Understanding GPM, LPM, and Water Pressure PSI For Commercial Applications

Water jetters and pressure washers are essential tools for efficient cleaning. Understanding their output measurements is critical to choosing the suitable machine for the job. Two key metrics to know are LPM (Litres Per Minute) or GPM (Gallons Per Minute) for water flow rate and PSI (Pounds per Square Inch) for water pressure.

Let’s break these down and explore how they impact cleaning performance.

What Are PSI and Flow Rate?

PSI (Pounds Per Square Inch) measures the water pressure a washer or jetter produces. Higher PSI units create a more robust water force, which is ideal for breaking through stubborn debris, cleaning hard surfaces, or removing graffiti.

Flow Rate (LPM or GPM) refers to the water volume passing through the washer or jetter per minute. A higher flow rate means more water is delivered, improving cleaning efficiency by flushing away dirt or blockages more effectively.

Together, PSI and flow rate determine the washer’s overall power, but for many commercial applications, a higher flow rate is critical for efficient job completion.

What Is The Difference Between GPM and LPM?

GPM and LPM measure water flow rate and are used interchangeably, depending on where you live. PSI (pounds per square inch) and flow rate are measured in GPM (gallons per minute) or LPM (litres per minute).

They work together to determine how efficiently and effectively a pressure washer cleans. PSI refers to the water pressure, which dictates the force needed to break up grime, stains, or embedded dirt. GPM or LPM measures the water flow rate, indicating how much water the washer delivers to rinse away debris.

LPM is most commonly used in Australia, but it’s handy to know the difference.

Litres per minute (LPM) is the standard measurement for water flow in Australia and most of the world. Gallons per minute (GPM) is used primarily in the US and UK, with 1 GPM equaling approximately 3.785 LPM (US) or 4.546 LPM (UK).

To convert between the two:

- 1 GPM = 3.785 LPM.

What Water Pressure PSI & Flow Rate Combination Should I Select When Choosing A Water Jetter Or High-Pressure Cleaner?

Deciding on the right combination will depend on how you want to use your jetter or pressure cleaner. For instance, a 3,000 PSI washer with 15.2 LPM delivers strong pressure and ample water flow, suitable for cleaning grease-stained driveways.

A 4,000 PSI washer with 7.6 LPM focuses on higher pressure but with less flow. This may be ideal for removing tough, small-area grime.

A 2,000 PSI washer with 30 LPM uses a lower pressure with a higher flow rate, covering large areas quickly.

The balance of PSI and flow rate matters.

‘High PSI excels at removing embedded dirt, while high LPM rinses thoroughly and covers more surface area, making tasks faster and more efficient. For example, cleaning a fleet of vehicles is quicker with high GPM, but removing rust may require higher PSI.’

Put simply, a higher flow rate means the machine can cover a larger area quickly, making it ideal for efficiency-driven tasks.

Why Flow Rate Matters for Commercial Jetters

For commercial jetters, such as those used in plumbing or drain cleaning, flow rate is the primary consideration.

- Clearing Blockages: A higher flow rate ensures that debris is moved through pipes effectively, even in large-diameter drains. For instance, a jetter with 31 LPM can handle drains up to 225mm in diameter.

- Speed and Efficiency: High flow rates reduce the time required for large-scale cleaning tasks, saving labour and operational costs.

While PSI helps break down obstructions, the ability to flush them out relies on water volume, making flow rate crucial in applications like drain jetting or industrial equipment cleaning.

How PSI and Flow Rate Work Together

PSI and flow rate complement each other. High PSI provides the power to dislodge grime, grease, or blockages, while a high flow rate washes them away efficiently. For instance:

- Light Cleaning (2,000–2,500 PSI, 10–15 LPM): This is suitable for cleaning machinery and vehicles.

- Industrial Cleaning (3,000–4,000 PSI, 15–20 LPM): Ideal for construction equipment, concrete surfaces, or oil removal.

- Heavy-Duty Jetting (5,000+ PSI, 20–30+ LPM): Designed for clearing tough drain blockages or large-scale cleaning.

Selecting the right balance ensures optimal performance without overloading your plumbing system or wasting water.

Choosing the Right Flow Rate For High-Pressure Equipment

Jetters

Commercial jetters like the RAMJET 5000 combine 5,000 PSI pressure with a 24.7 LPM flow rate, making them ideal for clearing stubborn drain blockages. The unit can also be upgraded to 31 LPM for enhanced capability. Jetters are fully self-contained and designed for ease of transport on utes or vans.

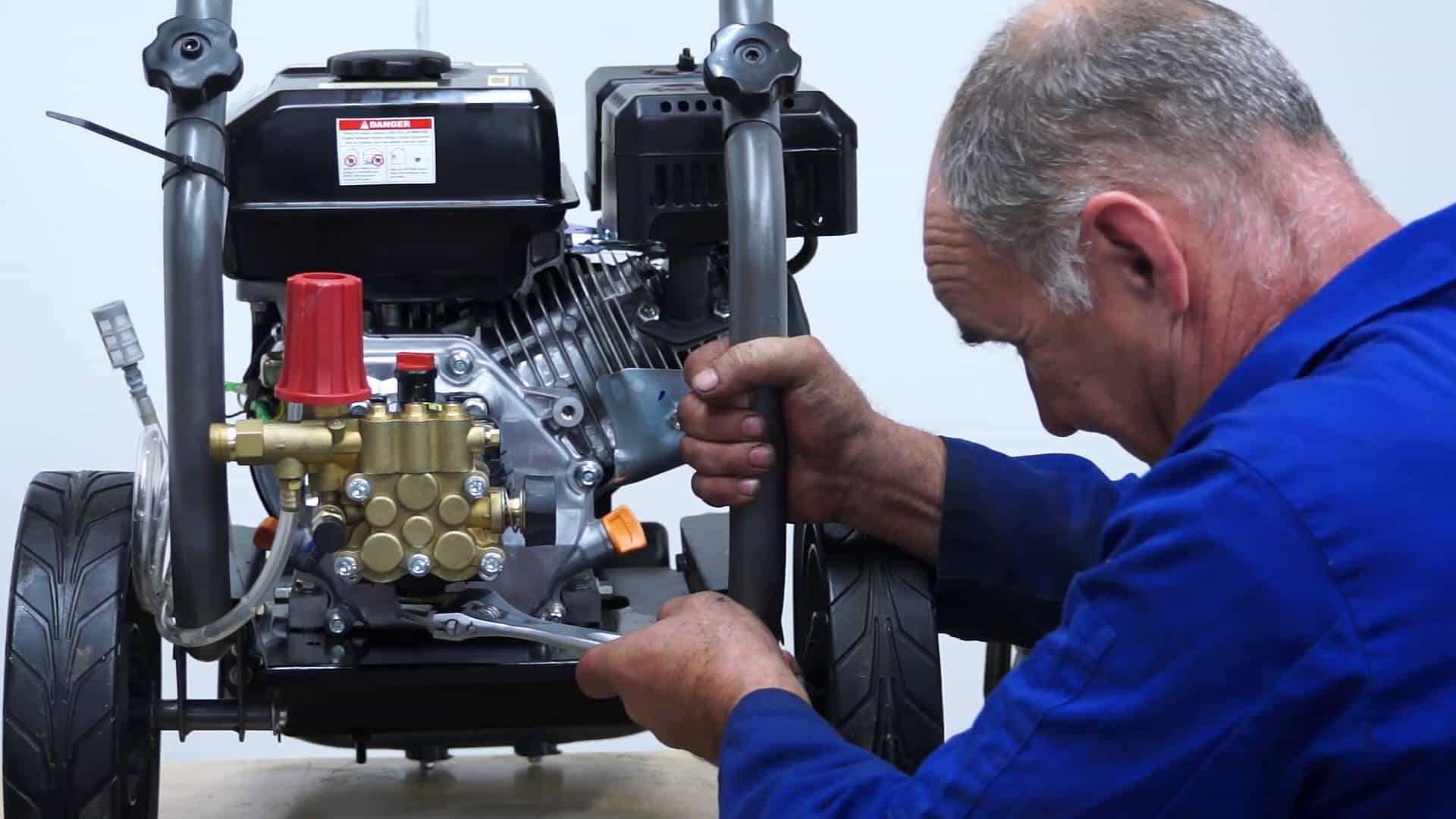

Commercial and Industrial High-Pressure Washers

For cleaning industrial equipment or maintaining large properties, high-pressure washers with adjustable PSI and high flow rates provide flexibility for various jobs. Hot water washers add extra cleaning power for grease or oil.

Considerations for Commercial Users

- Match Equipment to Your Job: Identify whether PSI, flow rate, or a combination of both is most critical for your application. Focus on flow rate for jetting; consider PSI for surface cleaning.

- Evaluate System Compatibility: Ensure your water supply and plumbing can handle the equipment’s pressure and flow demands.

- Regular Maintenance: Keep hoses, nozzles, and fittings in top condition to maintain performance and prevent downtime.

How Do GPM and PSI Work Together?

GPM and PSI complement each other:

- GPM determines how much water is delivered.

- PSI determines the force of the water.

For example, a machine with high PSI but low GPM might have the power to break through tough dirt but will take longer to clean large surfaces. Conversely, a machine with a higher GPM and moderate PSI can clean faster and more efficiently.

A good rule of thumb is that a higher flow rate (GPM/LPM) allows you to use less pressure (PSI) to do the same job efficiently.

If you’re choosing between two jetters with varying PSI levels, prioritising a higher flow rate (GPM/LPM) can often be more efficient. A higher flow rate means more water volume is delivered to the job, which allows you to clean effectively at a lower PSI. For example, a jetter with 24.7 LPM at 3,000 PSI can achieve the same cleaning results as a 15 LPM machine operating at 4,000 PSI, but it covers more surface area faster and reduces strain on the system.

‘In short? Higher flow equals faster, broader cleaning with less reliance on extreme pressure.’

Example Water Pressure PSI & Flow Rate Combinations

Here’s a sample guide of what different PSI and LPM combinations can achieve:

| PSI | GPM/LPM | Recommended Uses |

| 1,500 PSI | 2.0–2.5 GPM (7.5–9.5 LPM) | Cleaning outdoor furniture, small vehicles, and light dirt on patios. |

| 2,000 PSI | 3.0 GPM (11.4 LPM) | Cleaning cars, driveways, and siding. |

| 3,000 PSI | 4.0 GPM (15.2 LPM) | Washing large driveways and removing stubborn stains and graffiti. |

| 4,000 PSI | 5.0–8.0 GPM (19–30 LPM) | Heavy-duty industrial cleaning, including construction equipment. |

The Relationship Between Flow and Pressure

As a practical example:

- A pressure washer with 8 GPM and 1,500 PSI can clean more surface area faster than one with 4 GPM and 4,000 PSI, even though the latter has higher pressure. This is because a higher flow rate delivers more water, improving efficiency.

- However, higher PSI is essential for specific tasks, such as removing embedded stains or paint, where raw force is needed.

Key Components of a High-Pressure Cleaner or Water Jetter System

Water Pressure Gauge

Monitors the incoming water pressure to ensure it’s within the recommended range for safe operation.

Water Pressure Regulator

Maintains the correct pressure, safeguarding your equipment, hoses, and nozzles from damage.

Selecting the Correct Water Pressure PSI & Flow Rate For Commercial Use

For commercial applications, it’s essential to balance PSI and GPM/LPM for efficiency. Consider the following:

- For industrial use: Choose machines with 15–30 LPM and 3,000–4,000 PSI to ensure faster, more effective cleaning for large-scale tasks.

- For specialised applications, higher flow rates and PSI may be necessary to tackle tough, high-demand jobs, such as cleaning heavy equipment or surface preparation.

Also, ensure your water supply can handle the required flow rate to avoid interruptions and ensure optimal performance.

Our Services and Equipment

At Melbourne Jetter Centre, we provide high-quality pressure washers, jetters, and accessories for commercial and industrial clients.

We can help you with:

- Customised Recommendations: Offering tailored solutions to meet your specific industrial cleaning needs.

- Authorised Repairs and Servicing: Delivering expert maintenance to ensure your equipment stays in top condition.

- Accessories and Spare Parts: Supplying hoses, nozzles, and fittings to keep your equipment running smoothly.

Call Us Today

Looking for the ideal commercial pressure washer or jetter? Our team will help you understand key factors like pressure washer flow rate vs PSI to find the perfect solution.

Contact us today to ensure your equipment delivers maximum performance!